ORIGINS

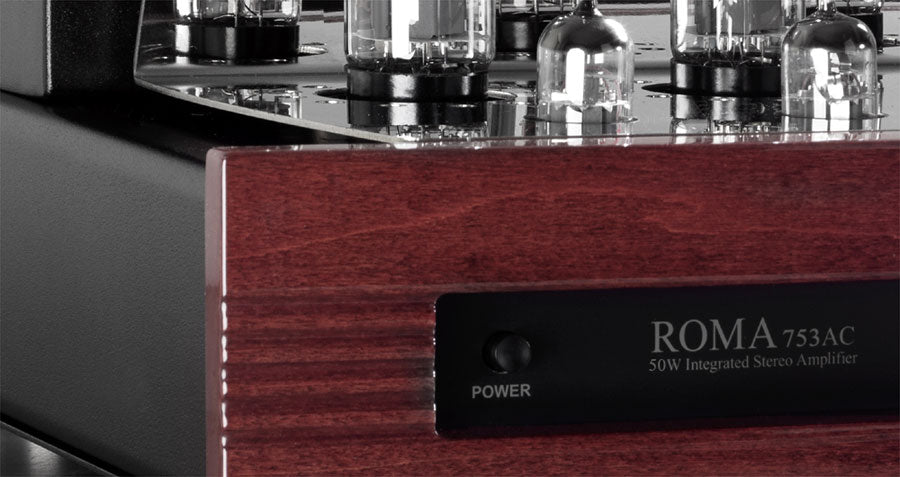

The idea for an entirely new kind of amplifier was first conceived by our engineers over a decade ago and development began in earnest in 2011. The objective was to set a new reference standard in high-end audio and music reproduction.

The result is Statement. Three years of relentless questioning, iterative design and a point blank refusal to accept no as an answer.

PERFORMANCE FIRST ENGINEERING

Product engineers often begin with what exists already. They might ask how something can work better, or where improvements can be made. With Statement, we started with a blank sheet of paper and a vision: to create the ultimate amplifier.

After the initial concept stage the engineering team set aside practical considerations and began to map out the product in free space. This creative freedom was then backed up by 3D computer models which confirmed the optimum position for each component.

To accommodate this new layout Statement pioneers a new vertical structure. It was the best way to minimise electromagnetic and mechanical interference and maximise thermal performance.

DUALITY IN DESIGN

Statement's radically different aesthetic may seem like a departure from Naim Audio tradition but it's the ultimate expression of everything we represent.

The imposing monolithic structure with its stark silhouette is offset by the organic sculptural flow of the heat sink and the beautifully lit volume control and central divide. This duality in the design reflects how our pursuit of technical brilliance is always grounded in the abstract human experience of music. If it's the best amplifier in the world in lab tests we’ve only done half a job - it's in the listening room where it really counts.

TECHNOLOGY

Everything about Statement is a leap forward in technology and design. It's been engineered from the ground up for pure performance.

ISOLATION

Statement perfectly represents our philosophy of providing the highest quality power supply, while isolating individual sections to avoid unwanted interference.

The NAC S1 and NAP S1 share the same fundamental layout. The noisy power supply is housed in the base and sensitive electronics are nestled above. Each section is divided by an acrylic centre-piece that blocks interaction. Top section electronics are separated further still, with internal chambers isolating individual stage

DUAL POWER

The Statement NAP S1 features a new bridged dual design with zero global feedback. The two stages are physically separated to optimise the amplifier circuit with the delicate voltage stage at the very top of the power amplifier, away from the current stage at the bottom.

Each mono power amplifier uses a huge 4000VA transformer to power speakers with precisely 746W (into 8 ohms). Precision engineering also makes sure every single watt is delivered right to where it's needed, when it's needed. After all, power is nothing without purpose.

CRAFT

Every component, curve and connection in Statement demanded new levels of engineering and tolerance.

METALLURGY

The distinctive ‘wave’ heat sinks begin life as a solid billet of untreated aluminium, which is cut to size and machined to achieve the curved profile. The fins are then cut using a five-axis, temperature-controlled, CNC machine. It takes three hours for the finished shape to emerge. Once each piece is individually machined, it is painstakingly hand-polished and quality inspected.

FINISHING

After the inspection process, the metalwork is submerged in baths of cleansing acid and then into a bath of electrolyte fluid containing black ink. A current is passed through it, bonding the ink to the metalwork and creating Naim Audio's signature black finish. It took several months of collaboration between our engineers and suppliers to achieve the finish Statement demanded.

HAND-CRAFTING

Statement has been designed and developed using cutting-edge manufacturing technology. But it takes a human touch to get things just right. For example, every sound-critical component is positioned and soldered by hand by our skilled technicians. As with all Naim Audio products final assembly is carried out by hand in Wiltshire, England.